litho printing Techniques Used by Top Print Shops

A Comprehensive Overview to Comprehending Litho Printing Techniques

The globe of litho printing, a strategy originating from the late 18th century, is a fascinating mix of history, technology, scientific research and art. Remain with us as we trip into the exciting realm of litho printing.

The Historic Advancement of Litho Printing

The historic trajectory of litho printing, a pivotal development in the realm of communication, is a fascinating tale of human ingenuity. The procedure progressed with the arrival of the rotary press, which substantially boosted performance. Each phase of litho printing's evolution showcases mankind's unrelenting quest of effectiveness and top quality in aesthetic communication.

Translating the Science Behind Litho Printing Inks

Moving on in the expedition of litho printing methods, the emphasis currently changes to the scientific research behind litho printing inks. The structure of these inks, their drying out procedure, and shade mixing techniques form the backbone of this complex art form. Understanding these aspects is critical to grasping the craft and accomplishing the desired print outcomes.

Structure of Litho Inks

In lithographic printing, the basic duty of litho inks can not be overemphasized. The structure of litho inks differs depending on its purpose, however usually, they are composed of 2 primary components - lorries and pigments. Pigments, the color-providing aspects, are carefully ground particles put on hold in the lorry, a liquid that lugs the pigment onto the printing surface area. The automobile is a complex combination of resins, solvents, and oils, which influence the ink's drying time, adhesion, and gloss. Furthermore, different ingredients are present to improve specific residential properties like flow, drying out, and resistance to ecological results. Each part plays a vital component in the last print's top quality, making the precise formulation of litho inks an elaborate science.

Ink Drying Refine

From the structure of litho inks, focus turns to the interesting procedure of ink drying. The drying out procedure is vital, as it influences the final print's high quality and longevity. Two main methods are used in litho printing: oxidative drying and absorption. Oxidative drying involves the ink responding with oxygen airborne to develop a difficult, completely dry film. This method offers a durable surface, but can be slower compared to absorption. Absorption, on the various other hand, entails the ink permeating right into the paper fibers, which is a quicker process yet can result in less vibrant shades. The selection in between these methods is reliant upon aspects such as print rate requirements, the paper kind used, and the desired coating.

Shade Mixing Methods

While the drying out process plays a crucial function in litho printing, the scientific research of shade mixing strategies holds equivalent significance. This is an intricate process that entails the careful blending of primaries: cyan, magenta, and yellow, in varying percentages to accomplish a wide variety of shades. The addition of black ink, called 'vital', assists in regulating the intensity and depth of the colors. The look at this website scientific research behind litho printing inks likewise thinks about the transparency of the ink, which influences exactly how shades overlay and mix. To accomplish a reliable shade mix, print professionals have to additionally comprehend the complexities of ink actions, color concept, and the physical buildings of the substrate on which the ink is used.

The Art and Layout Aspects in Litho Printing

Litho printing takes a breath life right into art and style through its distinct elements. Litho printing accommodates a selection of shades, enabling artists to develop dynamic and vibrant prints. This combination of precision and versatility makes litho printing a recommended selection for several musicians and developers.

Modern Applications of Litho Printing Strategies

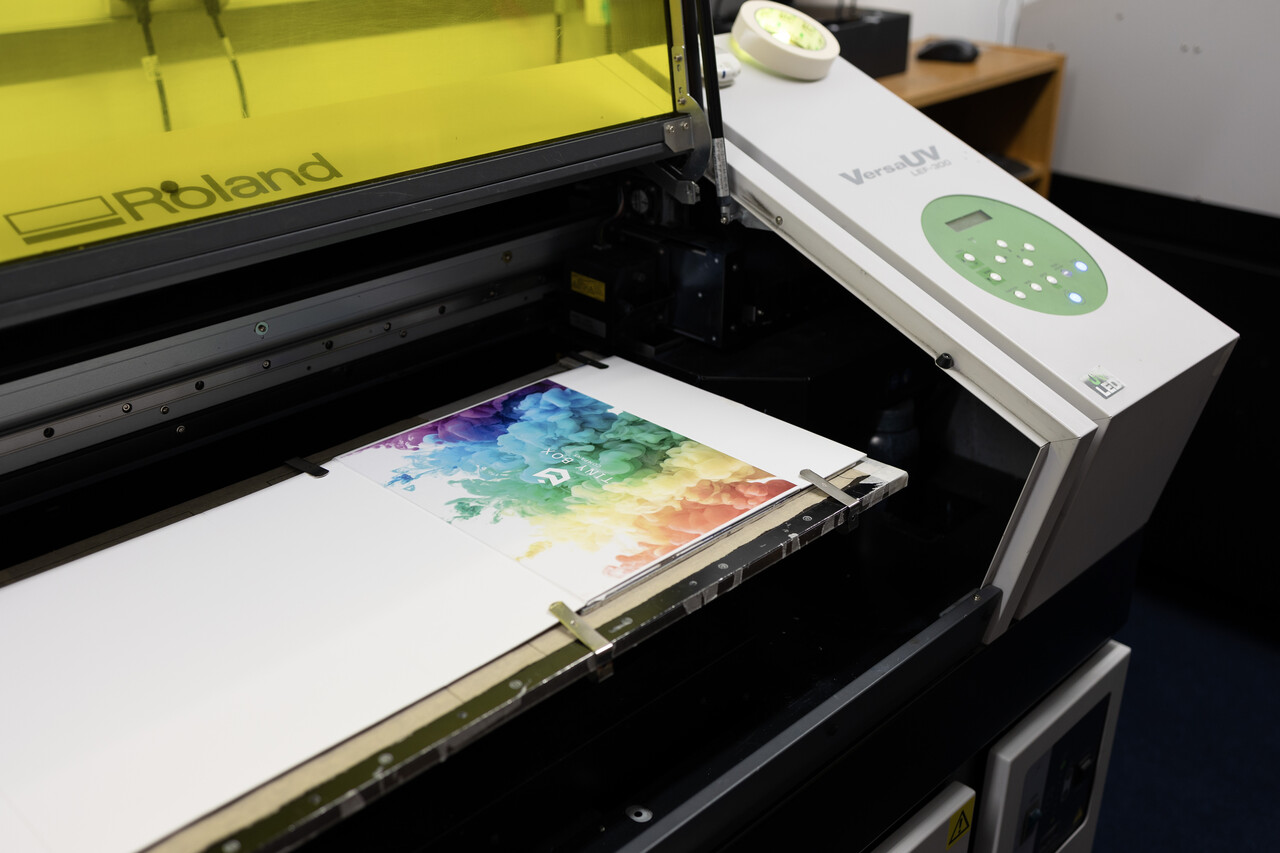

Litho printing link techniques have located extensive use in the modern commercial market. Its influence and significance remain to grow with the development of new innovations and technologies in the field. This area will certainly discover these contemporary applications and the transformative function they play in the printing sector.

Industrial Litho Printing Makes Use Of

Litho printing continues to be a vital part of the commercial sector. High-volume printing tasks, such as the manufacturing of publications, papers, and packaging, depend on litho printing for its capability to provide premium picture quality and price performance. Litho printing additionally supplies a wide shade range, exceptional to that of electronic printing.

Advancements in Litho Printing

Pushing the borders of traditional strategies, modern innovations have fueled a host of developments in litho printing. These developments have not just improved the quality and efficiency of litho prints however additionally expanded its application range. One famous development is digital litho printing, which integrates the virtues of electronic modern technology with litho's premium output. This hybrid model provides faster arrangement times, lowered waste, and enables on-demand printing. Another significant improvement is the introduction of dig this environmentally friendly inks. These inks, made from veggie or soy-based services, have considerably minimized the market's ecological influence. litho printing. In addition, the development of sophisticated plate technology has structured the printing procedure, leading to sharper images and improved color integrity. These developments underscore the enduring significance of litho printing in the modern-day globe.

Discovering the Refine of Litho Printing: Detailed

Obstacles and Solutions in Contemporary Litho Printing

Despite the precision and tradition that litho printing proudly upholds, it is not without its collection of contemporary obstacles. Digital litho printing permits for economical short runs and very easy customization, resolving the problem of variable information. Thus, while there are challenges, the litho printing market is proactively adapting to meet them head-on, guaranteeing its importance in the future.

Conclusion

In final thought, litho printing, with its abundant history and scientific ins and outs, holds a substantial place in the print sector. The future of litho printing pivots on its ability to adapt to these altering needs, verifying its long-lasting worth in an evolving market.